Overview

The KMS-12 intelligent armored movable metal enclosed switchgear is suitable for 3.6-12kV three-phase AC 50Hz power grids. It is used for receiving and distributing electrical energy, controlling, monitoring, and protecting circuits. It can be used for single bus section systems and double bus section systems. This product is a new generation of intelligent product designed and developed by our company based on advanced manufacturing technology borrowed from abroad. This product can provide real-time health status of devices through digital interfaces, detect potential equipment failures in advance, and meet the requirements of unmanned and regional monitoring center station management modes. It can receive and execute control instructions issued by the monitoring center, dispatch center, and local backend systems, and automatically complete relevant equipment control.

Characteristic

◆ Superior performance: The three compartments of the switchgear are equipped with pressure release channels to release the pressure generated by internal arc faults;

◆ High protection level: The switchgear has comprehensive measures to prevent misoperation. Install reliable mechanical interlocking to meet the "five prevention" requirements of the power system;

◆ High degree of intelligence: using the Internet of Things technology, edge computing technology and IEC61850 technology, through the access of various sensors to complete the mechanical characteristics analysis, electrical characteristics analysis, temperature characteristics analysis and other functions of the switchgear, to achieve the "self perception" of the health of the switchgear;

◆ One click visual sequence control: Power on (ground knife disconnected, chassis car shaken to working position, circuit breaker closed, spring energy storage) and power-off (circuit breaker disconnected, chassis car shaken to test position, ground knife closed) can be operated with one click on a remote computer;

◆ Maintenance of switchgear status: By collecting status information of on-site equipment, analyze the health status of on-site equipment, and activate different levels of alarm signals based on the analysis results. Inspection and planned maintenance can be upgraded to status based maintenance, effectively improving the work efficiency of operation and maintenance personnel.

◆ Real time video monitoring inside the cabinet: Through the video device inside the cabinet, the working position test position of the circuit breaker in the circuit breaker room and the closing position opening position of the grounding switch in the cable room can be observed remotely through real-time video monitoring, achieving safety and efficiency;

◆ Partial discharge monitoring: By using a partial discharge monitoring device to monitor insulation faults such as dendritic aging and breakdown of the cable body insulation and moisture ingress of accessories, potential hazards can be detected early and reasonable maintenance arrangements can be made to avoid serious accidents and improve the reliability of long-term equipment operation.

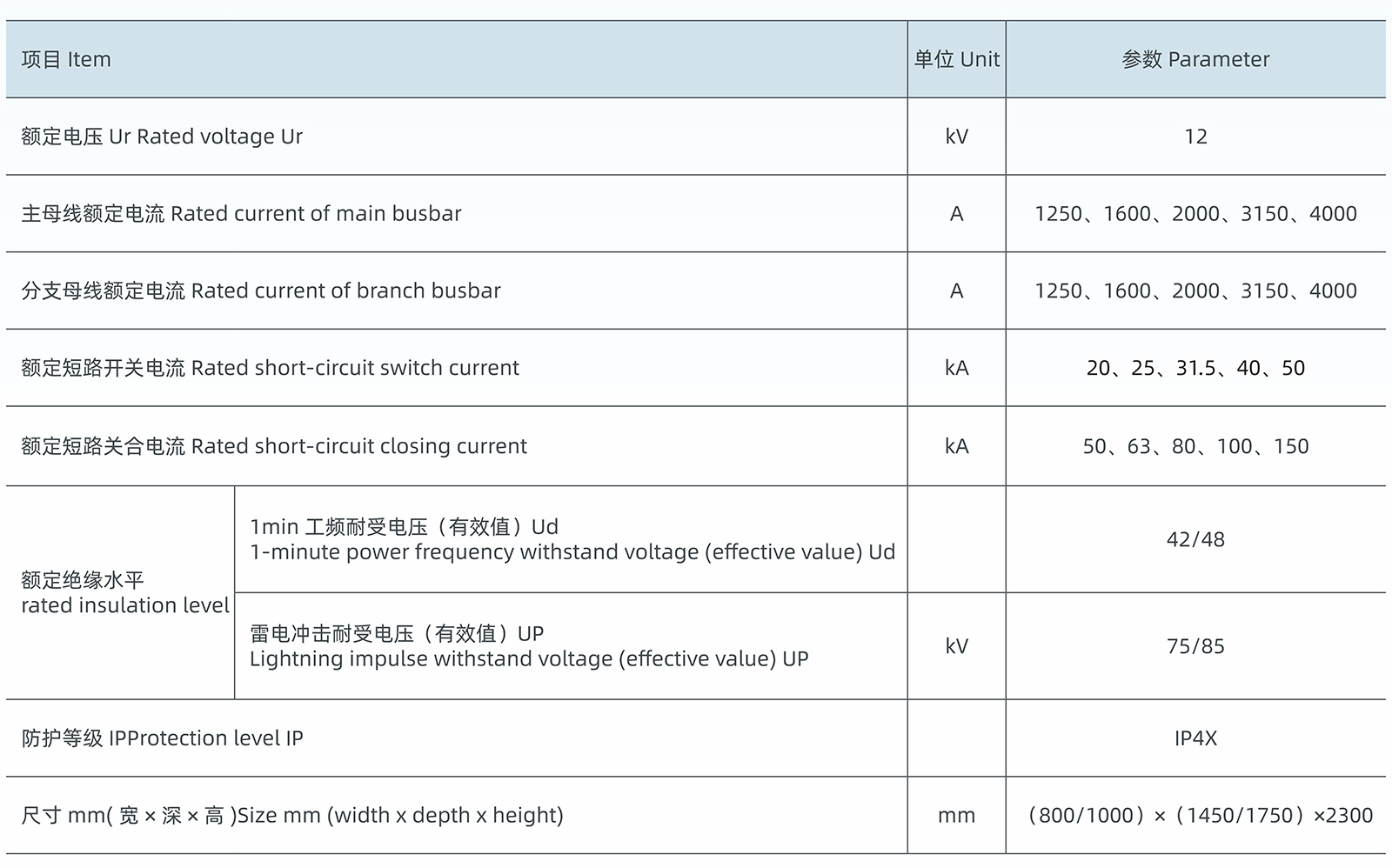

Technical Parameter