1.Overview

ZW口-12 Primary &. $econdary Deeply-integrated Pole-mounted Circut Breaker adopts the ful-sealed and insulated designmalinly used to achieve the segmentation and connection funclion of the main trunk cicuit of the 10ky power distribution network. Theproduct utilizes the ciocinc currenl transducer, volage sensor, capacitor power supply mocule, line loss acquisilion mocule, and otheradvanced technologies, able to adapt to the comprehensive local feeder automation funclion, This funcion enables it o be independeniof the master stalion and communicalion, adapt to the muli-branch &. multi-linked distribution nelvork framework by delecing he shortcircuilt'ground fault and conducling classiied proteclion, and implement the seleclive proleclion lor ine lauts. in case ot short circuiland singie-phase ground fault, it can quickly cary out the poslioning and aulcmalic isolalion in place, wihout allecing the powersuppiy in the non-fault area, to greally improve the relabily ol power supply. in addlion, the product has the functon oi calculaingaclive power, reaclive power, power faclor, frequency, and electric anergy, and can monitor the stalus ol the power syslem in a realtime marner, and fimely detect possible problems, to better manage and maintain the power system.in conclusion, the primary & secondary dleeply-integrated pole- mounted circult breaker is the intellgent power equlpment withhigh performance, able to improve the rellablty and eficlency of power supply, and reduce the fauts and maintenance costs ofpower systems, regarded as one of the important dilrections for development of future power distribution lines.

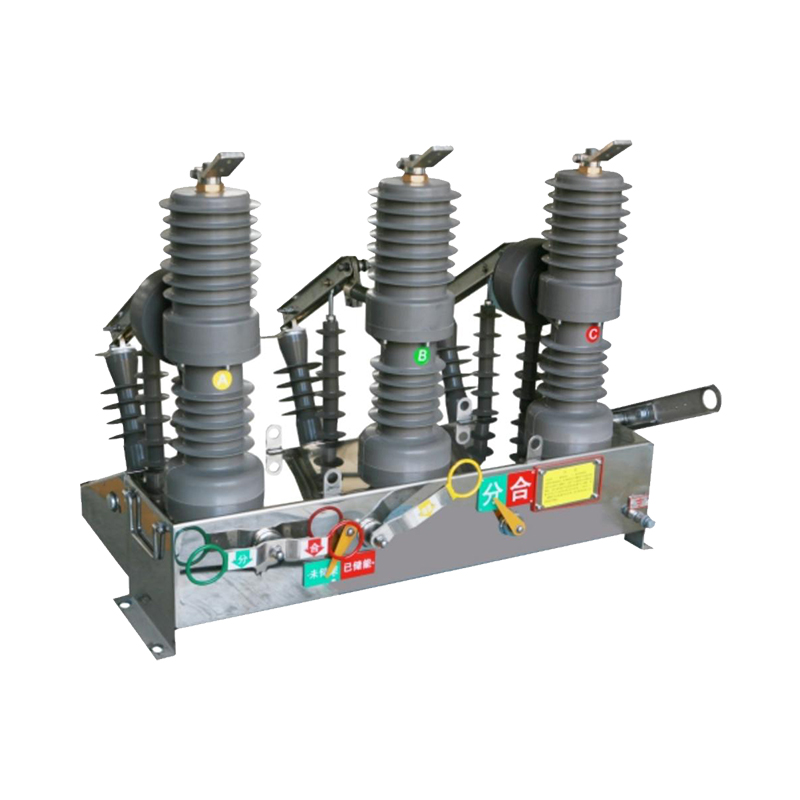

2. Structural characteristics

1. Safety: The primary equipment is deeply integrated wih the secondary equipment, to reduce the primary auxilary equipment,without increasing the risk of fallure: the linkage device is adopted to eliminate the potential safety hazards of accidental remoteconirol caused by automation.

2. Effeciveness: lmplement the selective tripping of short circuit faults (multi-level precise stage difarence coordination), realize theselective automatic isolation of single-phase ground faults (transient fault location).3.Advanced Nature: The product adopls the buit-in ECT and EVT, and uses the capacitor power supply technology to solve theproblem of terminal power supply. The shell utilizes the advancad manufacturing techniqwe to achieve the proteclion grade of iP87The partial discharge is not more than 20pC.

4. intellgeniization: The terminal work is independent of the master station. t can rely on the machine learning and original algonthmto automalically diagnose the short circuit or single-phase ground faut and give action commands.5. Usabilty: The operation is simple, with no nead of changing aperafion habits, adding operating todls and steps, and acceptingthe professional training, The product can conduct the factory commissioning, and the modular replacement for maintenance, andsupport the hot swapping, greatly reducing the dependence on professional technicians.G. Minialturizalion: The primary equipment is deeply integrated vith the secondary equipmant (having the built-in ECT and EVT), andthe weight is reduced by over 20kg, which lcwers the on-site construction difficulty and improves the installalion efficiency.